Have you ever experienced frustration while using your drill press due to the chuck slipping? If so, you’re not alone. In this blog post, we will explore the causes of drill press chuck slippage, providing you with useful insights to help you troubleshoot and prevent this common issue. So, if you’re looking for practical solutions to keep your projects on track, keep reading to discover the reasons behind this annoyance and how to address it effectively.

This image is property of pixabay.com.

Incorrect Chuck Installation

Improper tightening

When installing a chuck on a drill press, it is crucial to ensure it is properly tightened. If the chuck is not tightened enough, it can lead to slippage and cause issues during drilling. It is recommended to use a chuck key and tighten the chuck securely, making sure there is no wobbling or play in the chuck.

Insufficient tightening

On the other hand, overtightening the chuck can also lead to problems. If the chuck is tightened excessively, it can put excessive stress on the chuck jaws and cause them to deform or break over time. It is important to strike the right balance and tighten the chuck adequately without going overboard.

Worn Chuck Jaws

Excessive wear

Over time, the chuck jaws can wear down due to regular use. This wear can cause them to lose their grip on the drill bit, leading to slippage. If you notice that the chuck jaws have become smooth or rounded, it is a good indication that they need to be replaced. Regular inspection and timely replacement of worn chuck jaws can help maintain a secure grip.

Damaged or broken jaws

In some cases, the chuck jaws may become damaged or break entirely. This can happen due to over-tightening, using an improper chuck key, or accidental mishandling. Damaged or broken jaws will not provide a reliable grip on the drill bit, resulting in slippage. If you encounter such issues, it is essential to replace the chuck jaws promptly to ensure safe and efficient drilling.

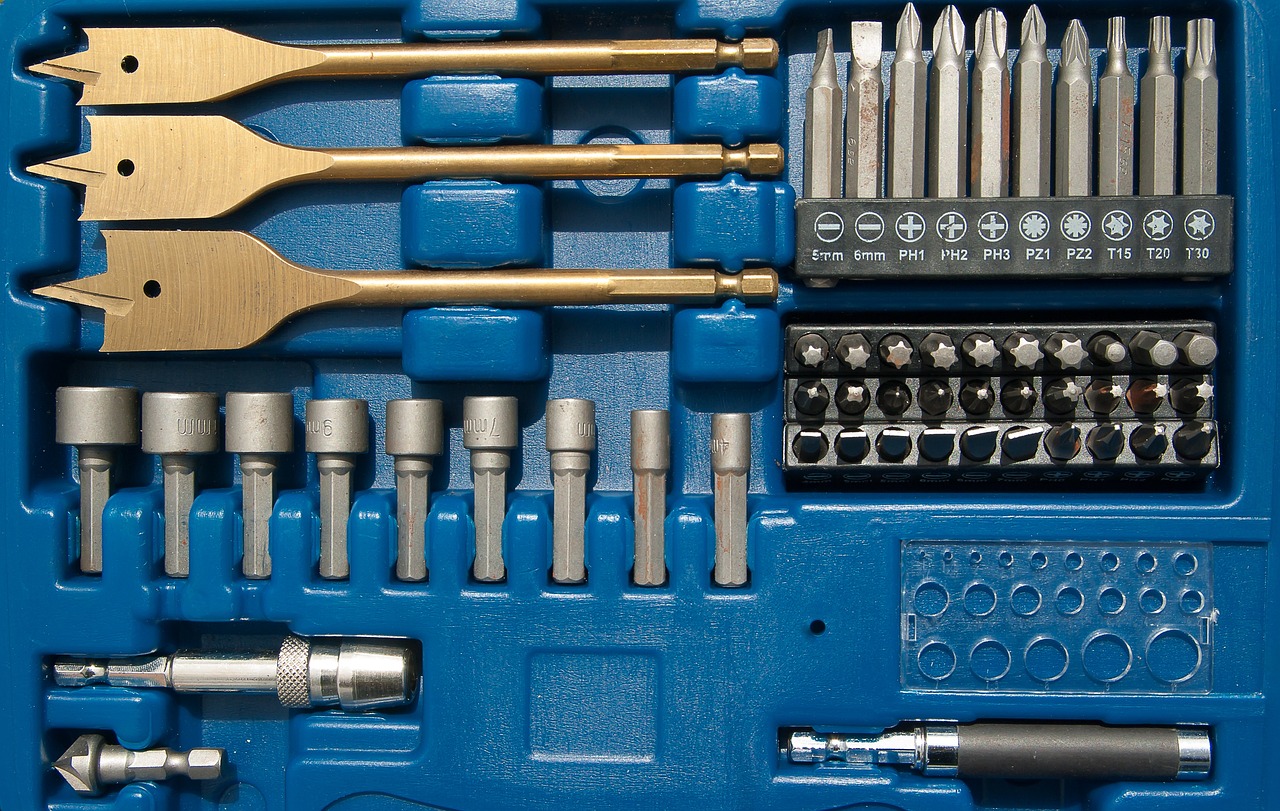

This image is property of pixabay.com.

Loose Drill Bit

Incorrectly tightened drill bit

If the drill bit is not tightened properly within the chuck, it can lead to slippage during drilling. Always ensure that the drill bit is inserted into the chuck securely and tightened using the chuck key. This will minimize the chances of the drill bit slipping or spinning within the chuck while in use.

Worn drill bit shank

The shank of the drill bit can also contribute to slippage if it becomes worn or damaged over time. A worn drill bit shank may not provide a snug fit within the chuck, leading to instability and slippage during drilling. Regularly inspect and replace worn drill bits to maintain a secure connection with the chuck.

Low Chuck Gripping Force

Faulty chuck key

A faulty chuck key can prevent the chuck from gripping the drill bit effectively. If the chuck key does not engage properly with the chuck teeth or is worn, it can result in low gripping force and slippage. It is advisable to inspect the chuck key for any signs of wear and replace it if necessary to ensure a reliable grip.

Deformed or worn chuck key

Over time and with repeated use, chuck keys can become deformed or worn out. This can affect their ability to engage with the chuck teeth and provide sufficient gripping force. Regularly inspect the chuck key for any signs of deformation or wear, and replace it if needed to avoid slippage issues while using the drill press.

This image is property of pixabay.com.

Excessive Vibration

Unbalanced drill bit

An unbalanced drill bit can cause excessive vibrations during drilling, which can lead to slippage. If you notice excessive wobbling or vibrations when the drill press is in use, it is likely that the drill bit is unbalanced. To address this issue, replace the unbalanced drill bit with a new one to ensure smoother and more stable drilling operations.

Loose or worn spindle bearings

The spindle bearings play a crucial role in maintaining stability and reducing vibrations in a drill press. If the spindle bearings are loose or worn out, they can cause excessive vibrations that can lead to slippage. Regular maintenance and inspection of the spindle bearings can help identify and address any issues promptly, ensuring smooth and stable drilling.

Lack of Lubrication

Dry or dirty chuck key

A dry or dirty chuck key can hinder smooth operation and reduce gripping force. Lubricating the chuck key regularly with a suitable lubricant can ensure smooth engagement with the chuck teeth and maximize gripping force. Additionally, keeping the chuck key clean prevents any dirt or debris build-up that may affect its functionality and lead to slippage.

Dry or contaminated chuck threads

The threads of the chuck that allow it to tighten and secure the drill bit can also be a source of slippage if they are dry or contaminated. Proper lubrication of the chuck threads with a suitable lubricant can ensure smooth operation and minimize the risk of slippage. Similarly, regular cleaning of the chuck threads prevents the accumulation of dust or debris that may affect its gripping ability.

Dust and Debris

Accumulation in chuck jaws

During drilling, dust, debris, and wood shavings can accumulate in the chuck jaws. This build-up can hinder the gripping force of the chuck, leading to slippage. To prevent this, it is essential to clean the chuck jaws regularly, removing any debris or build-up that may affect its performance. This will help maintain a reliable grip on the drill bit and reduce the chances of slippage.

Build-up in chuck mechanism

In addition to the chuck jaws, the chuck mechanism itself can also accumulate dust and debris over time. This build-up can affect the smooth operation of the chuck, potentially leading to slippage. Regular cleaning and maintenance of the chuck mechanism, including the removal of any built-up dust or debris, can help ensure consistent and reliable performance.

Overload

Using oversized drill bits

Using drill bits that are larger than the recommended capacity of the drill press can overload the chuck and lead to slippage. The chuck may not be able to securely grip an oversized drill bit, increasing the chances of it slipping or coming loose during drilling. Always use drill bits that are within the specified capacity of your drill press to avoid overloading the chuck and potential slippage issues.

Applying excessive pressure or force

Applying excessive pressure or force while drilling can also lead to overloading the chuck and causing it to slip. It is important to allow the drill bit to do the work and avoid exerting unnecessary force. Applying excessive pressure or force puts excessive stress on the chuck and can compromise its gripping ability, resulting in slippage. Maintain a steady and controlled drilling technique to avoid overloading the chuck.

Worn Chuck

Age-related wear

With regular use and over time, the chuck itself can experience wear and tear. The internal components of the chuck may wear down, affecting its gripping force and leading to slippage. While age-related wear is unavoidable, regular maintenance and inspection can help identify any issues with the chuck and allow for timely repairs or replacement to ensure continued reliable performance.

Internal damage

Accidental mishandling or excessive force during drilling can cause internal damage to the chuck. This internal damage can impair the chuck’s ability to grip the drill bit securely, leading to slippage. It is essential to handle the drill press with care, avoiding any excessive force or mishandling that may cause internal damage to the chuck. Regular inspection and maintenance can help detect any internal damage early on and prevent further slippage issues.

Inadequate Chuck Design

Inferior chuck materials

The materials used in the construction of the chuck can greatly impact its performance and durability. Inferior materials may not provide sufficient strength or wear resistance, leading to decreased gripping force and increased slippage. Investing in a drill press with a chuck made from high-quality materials can help avoid issues caused by inadequate chuck design.

Poor chuck manufacturing

Inadequate manufacturing processes can result in chucks with inconsistent tolerances, subpar components, or poor construction. These flaws can significantly impact the chuck’s ability to grip the drill bit securely, leading to slippage. It is important to choose a drill press with a chuck that is manufactured to high-quality standards to ensure reliable performance and minimize slippage-related issues.

By understanding the various causes of drill press chuck slippage, you can take the necessary steps to prevent and address these issues effectively. Regular maintenance, proper installation, and inspection of the chuck, drill bits, and associated components will help ensure a secure grip and reliable performance during drilling operations. Remember to prioritize safety and follow manufacturer guidelines to maximize the lifespan and functionality of your drill press chuck. Happy drilling!